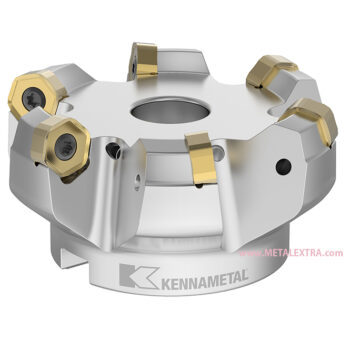

Kennametal Memperkenalkan grade terbarunya KCS10B Untuk Aplikasi bubut Superalloy Yang Digunakan Di Aerospace maupun industri mesin dan metalurgi yang membutuhkan ketahanan panas hingga lebih dari 700 °C!

Kennametal telah memperkenalkan grade pisau bubut terbarunya, KCS10B, untuk superalloy berbasis nikel, kobalt dan besi yang digunakan dalam aerospace dan aplikasi suhu tinggi lainnya.

KCS10B, yang memiliki lapisan revolusioner yang diaplikasikan pada substrat karbida butir ultra-halus untuk adhesi lapisan yang unggul, memberikan masa pakai alat hingga 50 persen lebih besar, proses yang lebih mudah diprediksi, dan peningkatan produktivitas ketika bekerja dengan superalloy yang sulit untuk dikerjakan. KCS10B mengatasi tantangan paling umum yang dihadapi dalam mengubah superalloy — kawah dan bentukan kedalaman — dua mode keausan yang sering menyebabkan kegagalan alat yang tak terduga dan bahkan bencana.

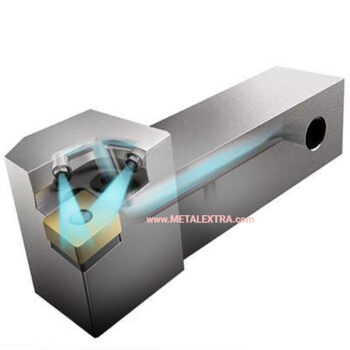

Sputtering Khusus

Dalam fisika, proses sputtering merupakan sebuah fenomena di mana partikel-partikel mikroskopis dari material padat dikeluarkan dari permukaannya, setelah material itu sendiri dihujani oleh partikel-partikel energik dari plasma atau gas.

Selama proses pelapisan PVD tradisional, teknologi High-Power Impulse Magnetron Sputtering (High-PIMS) Kennametal menghasilkan kabut halus AlTiN, membangun serangkaian lapisan logam keramik komposit yang sangat tipis, halus, dan tahan aus saat dipotong dengan kecepatan dan suhu yang tinggi.

Awet dalam pembubutan material Super Alloy!

Logam mahal seperti Inconel 718 dan Stellite 31 dikenal sangat kuat karena menyebabkan keausan yang cepat dan masa pakai alat yang tidak dapat diprediksi sebelumnya, Paduan logam Inconel 718 merupakan logam paduan kromium hardenablenickel zaman yang memiliki kekuatan creep-rupture yang tinggi pada suhu tinggi hingga sekitar 700 °C.

KCS10B terbukti mengurangi bentukan DOC dan memperpanjang masa pakai alat dari tiga menit menjadi lebih dari lima menit dalam operasi pengasaran. Kehidupan alat dalam menyelesaikan tarif operasi bahkan lebih baik, dengan kawah yang terlihat dan kegagalan alat selanjutnya sering tertunda oleh faktor dua atau tiga dibandingkan dengan merek yang kompetitif.

KESIMPULAN

Paduan pisau bubut Kennametal KCS10B mampu digunakan untuk machining dan penggilingan komponen super menjadi bagian-bagian yang kompleks. Karakteristik daya ketahanannya terhadap keretakan sangatlah luar biasa. Material super dari Inconel® 718 merupakan merek dagang terdaftar dari Haynes Alloys. Diterapkan pada substrat carbide ultrafine-grain yang sangat keras dan tahan aus, grade KCS10B sangat ideal untuk operasi pemesinan menengah dan finishing.

Jika Anda berminat untuk membeli alat kerja perbengkelan profesional ataupun beragam alat ukur dimensi metric lainnya silahkan hubungi kami melalui chat online yang ada di pojok kanan bawah website ini atau melalui email : sales@metalextra.com Semoga bermanfaat. Wassalam!

Sumber:

Kennametal Corporate Communications. AUGUST 2020.

Tim Kreatif Metalextra.com, Tulisan ini merupakan opini Pribadi di media milik sendiri.

Awalnya dipublikasikan pada2 January 2020 @ 11:41 AM